Winning the Aerospace R.H.H. Competition

Published:

Above is myself (right) and my teammates posing with our certificate at the 42nd Robert H. Herdon Competition!

TLDR Summary

Starting in May 2018, I began work with my team for our submission to the Robert H. Herndon Science Competition, a prototype CubeSat primarily marketed towards students and low budget science missions. Over the next year, we researched, designed, and developed our 1U CubeSat into a final deliverable. We then presented our finished product, affectionately named “The NubeSat,” one year later in June 2019 at the 49th R.H.H. Science Competition, for which we received first place.

The Project

What is the competition?

“Aerospace’s Robert H. Herndon Memorial Science Competition honors the legacy of aerospace pioneer Robert Herndon with competition events designed to stimulate engineering and STEM interest among underprivileged and minority students while increasing diversity in the aerospace industry.”

learn more here: https://aerospace.org/herndon

The NubeSat

Our submission for the 2019 competition was a prototype CubeSat bus we called “The NubeSat.” Marketed to highschoolers and students like ourselves, our idea was simple: as the launch systems and capabilities of big companies like SpaceX and Blue Origins grows, they will inevitably have more and more seating available for public-based projects. We aimed to create a “NubeSat” that provided all the bare bones necessities: GPS, wireless comms, power, and attitude control, to enable other students and or even dedicated hobbyists to install their own instrumentation in orbit and enable the next generation of space discovery. We made it a goal to completely understand the process of design and development so we could partner with prospective customers, implement their designs on our standard bus, and connect them to a launch seat.

While I don’t have the all the true technical specs of the NubeSat on hand anymore (this post is made well after I completed the projcet), I can share a few cool pictures along with all the features that it did have.

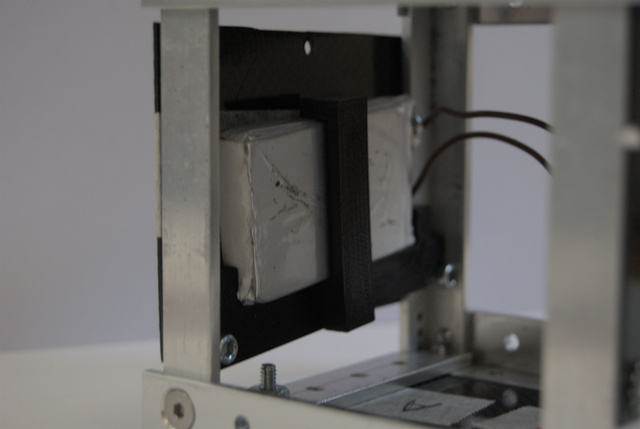

The battery system as attached to the 3D printed mounts we made, which also held on the solar panels.

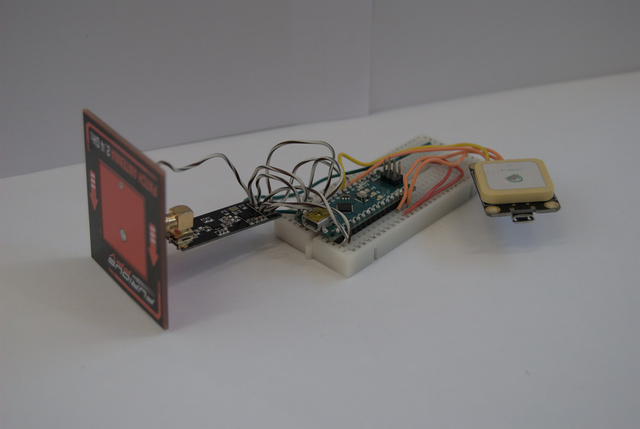

The second image shows the GPS system before we mounted onto the custom PCB we had printed at PCBExpressway. This antenna gave us a working range of over 1.5 miles.

Our NubeSat had all of the following features:

- Handmade aluminum frame and wiring

- Thermal insulation on the outside along specifically placed batteries to limit heat transfer and intake

- Battery power which maintained charge through use of external solar panels on 4 faces and a handmade charging circuit

- Two arduino nanos as the brain; one to control and talk with the patch antenna, and one that was designed to get info from the GPS, store it on an SD card, and send data to the patch antenna to be received.

- a custom printed PCB board that allowed all of our circuitry to fit comfortably on one layer of the cubeSat.

- a set of flywheels in the center that allowed for attitude control; by spinning the wheels at high RPM, the sattelite could turn about one or more axes.

What did I learn?

While the entire project was theoretical, and our budget was unfortunately too small to create a genuine protype ready to launch and demonstrate, I loved learning how to work as a team. In the research stages, I learned how to prepare for complex problems and generate solutions. As we assembled and co-operated our subsystems together towards a greater goal, I saw the critical importance of review and team communication. Together we overcome obstacles, met our deadlines, all while ensuring our final deliverable was a worthwhile and robust product.